Advertisement

-

Published Date

September 12, 2023This ad was originally published on this date and may contain an offer that is no longer valid. To learn more about this business and its most recent offers, click here.

Ad Text

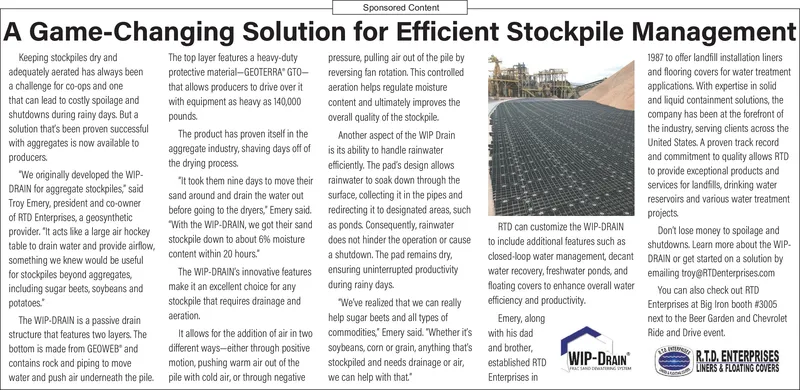

Sponsored Content A Game-Changing Solution for Efficient Stockpile Management pressure, pulling air out of the pile by reversing fan rotation. This controlled aeration helps regulate moisture content and ultimately improves the overall quality of the stockpile. Another aspect of the WIP Drain is its ability to handle rainwater efficiently. The pad's design allows rainwater to soak down through the surface, collecting it in the pipes and redirecting it to designated areas, such as ponds. Consequently, rainwater does not hinder the operation or cause a shutdown. The pad remains dry, ensuring uninterrupted productivity during rainy days. Keeping stockpiles dry and adequately aerated has always been a challenge for co-ops and one that can lead to costly spoilage and shutdowns during rainy days. But a solution that's been proven successful with aggregates is now available to producers. "We originally developed the WIP- DRAIN for aggregate stockpiles," said Troy Emery, president and co-owner of RTD Enterprises, a geosynthetic provider. "It acts like a large air hockey table to drain water and provide airflow, something we knew would be useful for stockpiles beyond aggregates, including sugar beets, soybeans and potatoes. The top layer features a heavy-duty protective material-GEOTERRA® GTO- that allows producers to drive over it with equipment as heavy as 140,000 pounds. The product has proven itself in the aggregate industry, shaving days off of the drying process. "It took them nine days to move their sand around and drain the water out before going to the dryers, Emery said. "With the WIP-DRAIN, we got their sand stockpile down to about 6% moisture content within 20 hours. The WIP-DRAIN's innovative features make it an excellent choice for any stockpile that requires drainage and aeration. The WIP-DRAIN is a passive drain structure that features two layers. The bottom is made from GEOWEB" and contains rock and piping to move water and push air underneath the pile pile with cold air, or through negative It allows for the addition of air in two different ways-either through positive motion, pushing warm air out of the "We've realized that we can really help sugar beets and all types of commodities," Emery said. "Whether it's soybeans, corn or grain, anything that's stockpiled and needs drainage or air, we can help with that." RTD can customize the WIP-DRAIN to include additional features such as closed-loop water management, decant water recovery, freshwater ponds, and floating covers to enhance overall water efficiency and productivity. Emery, along with his dad and brother, established RTD Enterprises in WIP-DRAIN RAC SAND D 1987 to offer landfill installation liners and flooring covers for water treatment applications. With expertise in solid and liquid containment solutions, the company has been at the forefront of the industry, serving clients across the United States. A proven track record and commitment to quality allows RTD to provide exceptional products and services for landfills, drinking water reservoirs and various water treatment projects. Don't lose money to spoilage and shutdowns. Learn more about the WIP- DRAIN or get started on a solution by emailing troy@RTDenterprises.com You can also check out RTD Enterprises at Big Iron booth #3005 next to the Beer Garden and Chevrolet Ride and Drive event. R.T.D. ENTERPRISES LINERS & FLOATING COVERS Sponsored Content A Game - Changing Solution for Efficient Stockpile Management pressure , pulling air out of the pile by reversing fan rotation . This controlled aeration helps regulate moisture content and ultimately improves the overall quality of the stockpile . Another aspect of the WIP Drain is its ability to handle rainwater efficiently . The pad's design allows rainwater to soak down through the surface , collecting it in the pipes and redirecting it to designated areas , such as ponds . Consequently , rainwater does not hinder the operation or cause a shutdown . The pad remains dry , ensuring uninterrupted productivity during rainy days . Keeping stockpiles dry and adequately aerated has always been a challenge for co - ops and one that can lead to costly spoilage and shutdowns during rainy days . But a solution that's been proven successful with aggregates is now available to producers . " We originally developed the WIP DRAIN for aggregate stockpiles , " said Troy Emery , president and co - owner of RTD Enterprises , a geosynthetic provider . " It acts like a large air hockey table to drain water and provide airflow , something we knew would be useful for stockpiles beyond aggregates , including sugar beets , soybeans and potatoes . The top layer features a heavy - duty protective material - GEOTERRA® GTO that allows producers to drive over it with equipment as heavy as 140,000 pounds . The product has proven itself in the aggregate industry , shaving days off of the drying process . " It took them nine days to move their sand around and drain the water out before going to the dryers , Emery said . " With the WIP - DRAIN , we got their sand stockpile down to about 6 % moisture content within 20 hours . The WIP - DRAIN's innovative features make it an excellent choice for any stockpile that requires drainage and aeration . The WIP - DRAIN is a passive drain structure that features two layers . The bottom is made from GEOWEB " and contains rock and piping to move water and push air underneath the pile pile with cold air , or through negative It allows for the addition of air in two different ways - either through positive motion , pushing warm air out of the " We've realized that we can really help sugar beets and all types of commodities , " Emery said . " Whether it's soybeans , corn or grain , anything that's stockpiled and needs drainage or air , we can help with that . " RTD can customize the WIP - DRAIN to include additional features such as closed - loop water management , decant water recovery , freshwater ponds , and floating covers to enhance overall water efficiency and productivity . Emery , along with his dad and brother , established RTD Enterprises in WIP - DRAIN RAC SAND D 1987 to offer landfill installation liners and flooring covers for water treatment applications . With expertise in solid and liquid containment solutions , the company has been at the forefront of the industry , serving clients across the United States . A proven track record and commitment to quality allows RTD to provide exceptional products and services for landfills , drinking water reservoirs and various water treatment projects . Don't lose money to spoilage and shutdowns . Learn more about the WIP DRAIN or get started on a solution by emailing troy@RTDenterprises.com You can also check out RTD Enterprises at Big Iron booth # 3005 next to the Beer Garden and Chevrolet Ride and Drive event . R.T.D. ENTERPRISES LINERS & FLOATING COVERS